University of Toronto engineering students recently completed a project that was out of this world, in more ways than one.

They brought the far-off prospect of a mission to Mars a little closer to reality by devising a possible solution to a problem with long space travel: the need to pack light and yet bring everything necessary.

With help from their supervisor Professor Cathy Chin (ChemE), and advisors at NASA, the undergraduate students came up with a way to make organic products like food, pharmaceuticals and fuel using elements of the Martian atmosphere.

Of course, the U of T project would require much more testing before it could safely make the 54.6-million-kilometre trip through space. However, it shows promise, according to NASA environmental scientist John Hogan.

“Their work may have real applications,” he told U of T News. “Both in future of Earth and in space, being able to efficiently manufacture materials from carbon dioxide will be a very valuable capability.”

Using carbon dioxide, which is abundant on the red planet, the U of T students say astronauts can follow a two-stage process to make acetic acid – a key component in vinegar – in bioreactors. (A bioreactor is a vessel in which living organisms, particularly bacteria, synthesize useful materials.) They chose that compound because there are well-established processes for making it, and it can be easily metabolized by bacteria to make useful things in bioreactors, explained Stephanie Gaglione (ChemE 1T6+PEY), one of the team members who will be starting at Oxford University this fall on a Rhodes Scholarship.

“Organisms can make very complex products that can’t be made by just mixing together chemicals,” she said, “but you need to feed these organisms some type of source that has carbon in it.”

It was up to the mechanical engineering students, with expertise in thermodynamics, to test the concepts and see if they made sense within the constraints of a Mars mission.

“As a mechanical challenge, it’s a really interesting system,” said Kate Lonergan (MechE 1T6+PEY). “As soon as you send anything into space it just takes on so many extra considerations.”

Among other design challenges, the system had to have a lifespan of at least 1,000 days, need little maintenance and be safe to operate, even in case of failure so as not to endanger the astronauts.

The students say the system is capable of producing 24 kilograms of acetic acid per day and is 70 per cent more efficient than shipping everything needed to the planet. NASA’s target for a mission to Mars is the 2030s.

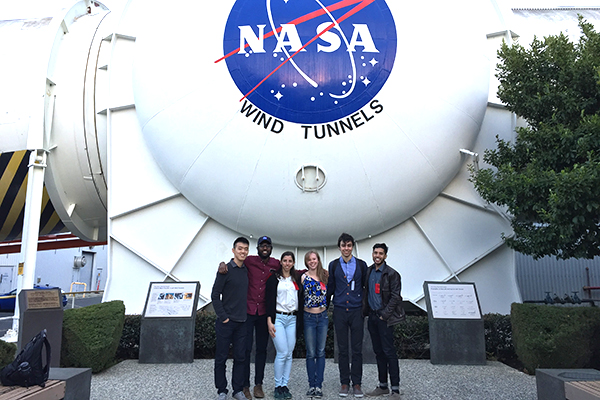

In the spring, Hogan, the NASA scientist, invited the student team — Haroon Dawood (ChemE 1T6+PEY), Gaglione, Jason Martins (ChemE 1T6+PEY), Lonergan, Madhushan Perera (ChemE 1T6+PEY) and Kevin Wang (MechE 1T6+PEY) — to NASA’s Ames Research Center in Mountain View, Calif. for a tour.

The students were shown around the thermal protection systems branch, where they saw heat-shielding technologies that allow spacecraft to re-enter Earth’s atmosphere, and the labs of the bioengineering branch, where they were shown waste processing, water recovery and synthetic biology labs.

“I hope that [the U of T students] see that space exploration is an endeavor that expands the mind to new possibilities,” Hogan said in an interview.

The project was part of U of T Engineering’s Multidisciplinary Capstone Design Course, an opportunity for engineering students of different backgrounds to work together on topics like airplane engine design or health-care delivery with advice from industry partners.

Martins, a Gates Cambridge Scholar, said the work was eye-opening. “I was most surprised to learn that there are many processes and pathways to utilize carbon dioxide, rather than just treating it as a polluting greenhouse gas,” he said.

The U of T Engineering students are optimistic that their work has paved the way for further research into manufacturing basic materials on Mars – maybe even earning them a tiny footnote in the history of space exploration.

“It would be nice to see someday when [the mission to Mars] does succeed that we made even the smallest of contributions to it,” Gaglione said.

This story originally appeared on U of T News. Story written by Geoffrey Vendeville.