Four U of T Engineering students are preparing for the flight of a lifetime. Their team has earned the rare chance to carry an experiment they designed onto a Falcon-20 jet, an aircraft similar to those used to train astronauts. Their goal is to better understand how liquids flow in microgravity, and to explore how 3D printers could make long-term space missions more feasible.

Team AVAIL (Analyzing Viscosity And Inertia in Liquids) — consisting of Neell Young (EngSci 1T4 + PEY, MASc Student UTIAS), Caulan Rupke, Michael Lawee and Andrew Ilersich (all Year 4 EngSci) — is among four chosen to participate in the Canadian Reduced Gravity Experiment Design Challenge (CAN-RGX), supported by the National Research Council and the Canadian Space Agency. The competition aims to create “tangible student-led impact in space exploration and development.”

For their project, Team AVAIL chose to focus on a phenomenon known in physics as the “liquid rope coil” effect. On Earth, this is seen most easily when a thick liquid like honey or maple syrup is poured from a spout or a spoon — the liquid flows in a way that looks like a coiling rope.

Watch video of the liquid rope-coil effect

Despite its commonplace nature, the phenomenon isn’t well understood. “We were surprised that this hasn’t been given the full treatment yet in the scientific literature,” says Ilersich. “It turns out to be a very complex process to describe mathematically.”

But the liquid rope coil effect is more than just a curiosity. In 3D printers, melted thermoplastics flow under pressure from nozzles before hardening to form the desired product. These plastics behave as a viscous liquid that is similar in many ways to honey or maple syrup. Because of this, understanding the liquid rope coil effect — including how it is affected by microgravity — is an important prerequisite to the use of 3D printers in space.

3D printing could address a key challenge for space missions: the need to minimize the space and weight of materials needed for the trip. Rather than bringing along all of the tools and spare parts they might possibly need, astronauts could instead manufacture objects on an as-needed basis. Because raw materials like thermoplastics can be packed much more tightly than tools of varying shapes and sizes, the approach could make long-term missions like a trip to Mars more feasible. “We think our project was chosen because of its novelty and its applications,” says Ilersich.

A better understanding of the physics behind the rope coil effect would also have applications here on earth. With a reliable mathematical model, the effect could be controlled to create coils that could be woven together into materials with customized strength, flexibility “springiness.” New porous materials could be created for use in tissue engineering, filtration and catalysis.

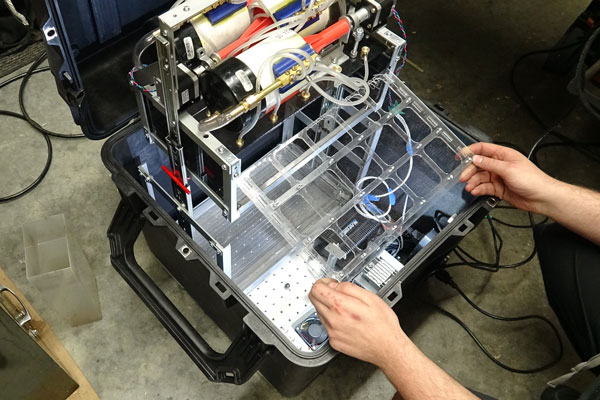

To watch rope coiling in microgravity, the team custom-built a self-contained experiment that had to fit inside the 50 cm x 50 cm x 50 cm box provided by the flight organizers. Because existing off-the-shelf pumps did not meet their needs, the team custom built a system that carefully controls the flow of a viscous liquid — in this case corn syrup — through fifteen different nozzles. A video camera inside of the box will record the rope coiling of the liquid, and custom-built software will analyze it.

To simulate microgravity, the team will carry their apparatus onto a Falcon-20 Research Aircraft, a jet modified for parabolic flight paths that simulate a reduced gravity environment.

“None of us has any experience with this kind of flight, so I’m heading to Canada’s Wonderland to ride all of the roller coasters for training,” jokes Rupke.

Team AVAIL will be in Ottawa July 24 to 28 for three days of training and their flight. They will experience twelve to fourteen parabolic flights of about 20 seconds each.

“This project has been an exciting introduction to the research process,” says Ilersich. “I’ll draw upon everything I learned here when I do my undergraduate and graduate theses, and potentially in a research career after I graduate.”

Follow Team AVAIL’s progress on Twitter and YouTube

This article was originally posted by Christina Heidorn in U of T Engineering News